The most common container types

A dry storage container is the most popular type of shipping container. They have lengths of 20, 40, and 45 feet and are designed to convey dry products.

These containers cannot transport chemicals or perishable foods because they cannot manage temperature. The majority of long-distance freight in international trade is transported in shipping containers.

The most popular shipping containers on the market are the 40-foot container and its 20-foot twin. They offer a few advantages over tankers and reefers in addition to being less expensive. Scroll down to learn more.

Given the millions of commodities sent around the world each year, it should come as no surprise that some types of container ships require goods of all sizes and shapes to fit inside containers.

Due to the high demand, both specialized and standard freight containers are required. To reduce space, expedite operations, and accommodate a variety of commodities, standard containers must be easy to stack.

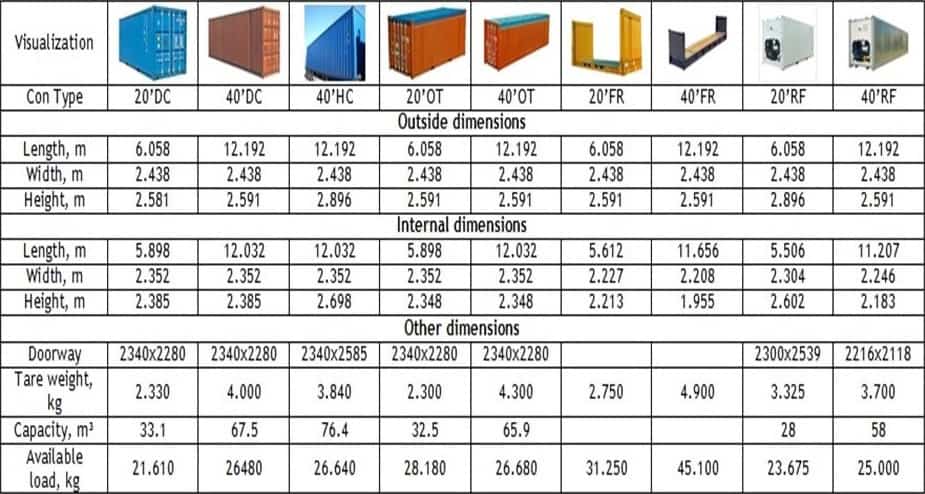

Before delving deeper into the 40-foot container, let’s start with a high-level overview of the 20-foot container.

The decision between a 20ft and a 40ft shipping container is influenced by a number of variables, including the type of freight being shipped, the destination, and the cost. The following are the benefits of each size of container:

Benefits of a 20-foot container:

20ft containers are often less priced than 40ft containers, making them a more economical option for smaller shipments.

Maneuverability: 20-foot containers are easier to manoeuvre, which can be advantageous in confined places or when loading area access is restricted.

20-foot containers are more versatile in terms of transport alternatives, as they can typically fit on smaller vehicles and be transported by rail with greater ease.

Benefits of a 40-foot container:

40-foot containers have twice the storage capacity of 20-foot containers, making them excellent for transporting larger goods or bulky cargo.

When transporting a significant quantity of cargo, a 40ft container can be more efficient because it can hold more cargo per container, thereby lowering the number of containers required.

Security: 40-foot containers typically have more sophisticated security features, such as locking systems and CCTV cameras, which might be crucial for high-value cargo.

The choice between a 20ft and 40ft container will ultimately depend on the precise requirements of your shipment, including the type of cargo, the distance to be travelled, and your budget.

Dry containers, in essence, are steel boxes used to transport a variety of items. Because dry containers provide limited insulation, products must be temperature resistant. As a result, you routinely mail items such as papers, clothing, and so on in dry containers.

They are also known as standard freight containers since they are the most popular box among container buyers and sellers, and they are typically acquired in 20- and 40-foot sizes.

The most common container sizes in use today are 20 and 40 feet. Furthermore, they are usually referred to as dry containers and Conex boxes, the container that gave birth to modern shipping.

The 20-foot cargo container, also known as a Twenty-foot Equivalent Unit (TEU), has become the industry standard. TEU is now commonly used to represent cargo volume and vessel capacity.

The abbreviation for 40-foot containers, which are equivalent to two TEUs, is Forty-foot Equivalent Unit (40ft).

Consider sea freight forwarding 18,000 iPads, 48,000 bananas, or 200 full-sized mattresses. It may also be loaded with twice as much using a 40-foot container.

Containers are usually made of steel or aluminium. For the optimal stacking, the containers must be the same size. The International Organization for Standardization (ISO) has mandated standard container sizes for the whole industry.

In this aspect, the 20-foot and 40-foot Dry Van container sizes are similar. They are known as dry vans because they can transport most dry material.

Anything from boxes, barrels, and pallets to already-hanging garments can be used. in addition to everything in between.The interiors of the containers can be modified to accommodate the vast majority of dry freight.

Like Dry Storage containers, but without a lid, this type of storage unit is ideal for use in wet environments. This facilitates the loading of bulky goods. A plastic roof can be attached to the container and secured with ropes to keep out the rain and other forms of precipitation.

Drayage services include overheight frames are used to transport equipment of this sort since the load may exceed the height of the shipping container.

Equiped with doors on both ends of the container, tunnel container storage design helps to unload or load cargo quickly.

One long side of an open-side container can be opened completely. This is helpful for items that are too wide to easily fit through the door of a tunnel container or dry storage container.

The side opens like a pair of doors, but it may be locked in place if necessary to keep your merchandise safe.

Making a wider room for loading and unloading shipments, it’s equipped with double doors. Commonly filled with construction materials including iron, steel etc., in sizes of 20ft and 40ft.

There is no roof or sidewalls on a flat rack container. As a result, bulky items can be loaded onto the rack from above or to the side with ease. The standard length for a flat rack container is 20 feet, however they can also be 40 feet in length.

Not all flat rack containers are rigid; some can be folded down, while others have optional walls that may be connected to the framework.

Tanks are containers with the speciality of storing fluids. Due to the chemicals they transport, they are typically made from corrosion-resistant materials.

Besides liquids, tanks can also be used to store sugar and other dry products.

A unique kind of intermodal container called a reefer, commonly referred to as a refrigerated container, is made to transport perishable items that need to be kept at a steady temperature.

Despite having its own internal refrigeration system, a reefer still needs to be powered by outlets (also known as “reefer points”) on the dock, inside the container, or somewhere else.

The container can be equipped with diesel generators (“gen sets”) that can run while it is being transported on a trailer or rail wagon.

In refrigerated containers, temperatures between -65 and 40 degrees Celsius can be maintained.

These containers are only half the height of standard containers and are made primarily of steel. Typically used for goods that need minimal effort to load and unload, such as coal, stones, and the like. More and more Containerized Bulk goods is being shipped in these containers.

These containers are equipped with regulated temperature control to maintain a higher temperature. Most suitable for long-distance transportation of products.

Elevate your supply chain with the optimal intermodal capacity solutions across North America, courtesy of Paige Logistics. Our team, comprised of marine container solution experts, boasts unparalleled connections with leading steamship lines and their strategic container repositioning lanes. This synergy cultivates a robust network of containers capable of handling heavier payloads, ensuring your logistics operate at peak efficiency.

Paige Logistics offers a versatile selection of containers, including 20 ft., 40 ft., 40 ft. high cube, and 45 ft. options, ensuring you only pay for the space your cargo requires. With the ability to accommodate loads up to 44,000 lbs, we guarantee that even your most substantial shipments will benefit from our reliable and cost-efficient intermodal marine container services.

Regardless of the rail or steamship line handling your container, Paige Logistics promises comprehensive end-to-end visibility. Our unique data exchanges and strong industry relationships empower us to provide you with proactive updates and insights, ensuring smooth transit for your freight across Canada and the USA North, and keeping you one step ahead of any potential disruptions.

Customized storage containers come in a wide variety of sizes and shapes. Items that can’t be stored in a standard shipping container are transported using them.

Because of the high costs associated with manufacturing and delivering specialized containers, most Canadian shipping companies try to avoid using them. To be fair, this is required for some loads.

Be it a container from China to Canada or shipping from Canada to USA or specifically hotter places like shipping refrigerated freight from Canada to California. With the right implementation from Paige Logistics, we can revolutionize your supply chain with our award winning dedicated transport and logistics services and keep your products fresh and safe during transit.

Stuck for finding the best freight forwarder China to Canada?

Shipping with Paige Logistics! Offering extended cross border shipping Canada to California.

2023 Global Leader In Shipping

Freight Carriers Association of a Canada

Author & Chief Executive Officer at Paige Logistics Ltd. → Experienced Operations Manager with a demonstrated history as a leader in the Freight Shipping, Transportation, Trucking and the Railroad Industry.